Logic Board Repair Services

Repairing a logic board is often faster and far more economical than sourcing a replacement. Many OEM boards are discontinued or have long lead times, which can extend downtime and increase costs. ACS helps companies avoid those delays through precise diagnostics, expert component-level repair, and complete functional testing before shipment.

Why Choose ACS for Logic Board Repair

ACS Industrial Services combines decades of field experience with a focus on technical accuracy and customer support. Each repair is performed in a fully equipped facility staffed by technicians who specialize in industrial and commercial electronics.

Key advantages include:

- Over 25 years of experience repairing logic, control, and circuit boards for industrial and commercial clients.

- Highly trained technicians skilled in diagnosing faults at the component and system levels.

- Free evaluation with no obligation or hidden costs: customers pay only for shipping.

- Two-year warranty covering both parts and labor, not just the replaced components.

- Cost savings of up to 80% compared to replacement.

- Nationwide service with consistent repair quality, regardless of customer location.

Repair vs. Replace - Why Repairing Makes Sense

Repairing offers several key advantages:

- Cost Efficiency: A repaired board typically costs a fraction of a new one, with savings of up to 80%.

- Reduced Downtime: Most standard repairs are completed in about three weeks. For urgent needs, ACS offers a Rush Repair Service that returns units within three to five days.

- Sustainability: Repairing extends the lifespan of existing equipment and prevents unnecessary electronic waste.

- Availability: Many older boards are no longer manufactured or supported by OEMs. Repairing them keeps critical systems operational without redesigning controls.

- All you pay is shipping.

- No Estimates - No Surprises ... Accurate Quote within 72 hours.

- Replace or Repair? Why Guess ... send us your item and then decide.

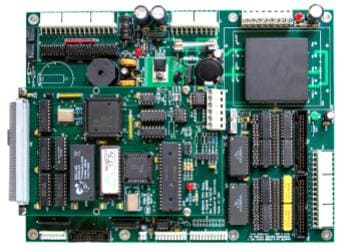

Our Logic Board Repair Capabilities

ACS Industrial Services is equipped to handle a wide variety of industrial and commercial logic board types. Each board that arrives at the Hickory, North Carolina facility undergoes a full inspection to determine the root cause of failure. Whether the problem stems from power irregularities, heat damage, or component degradation, every repair follows a repeatable, precision-driven process.

Supported Manufacturers

ACS supports hundreds of logic and control board models across major OEMs in the manufacturing, automation, and industrial electronics sectors. The engineering team continually expands this list as new technologies enter the market.

Customers who do not see their manufacturer listed can still submit a board for review. In most cases, ACS can repair it or recommend an alternative solution that prevents unnecessary replacement.

View our Supported Manufactures

Common Components and Issues We Repair

Industrial environments expose circuit boards to heat, vibration, electrical noise, and contamination. Over time, these conditions can lead to faults that affect performance or cause total system failure. ACS technicians are trained to identify and resolve a broad range of problems, including:

- Failed microprocessors and relays

- Power regulation and driver circuit faults

- Damaged solder joints, traces, and connectors

- Integrated circuit (IC) replacements and re-soldering

- Logic faults and firmware-related issues

- Surface-mount and conformal-coated board repairs

Each board is carefully cleaned and restored during the repair process. Damaged components are replaced with OEM-grade or equivalent parts that match the original specifications. Circuit integrity is verified using both in-circuit and functional tests before the unit is approved for return.

Diagnostic and Testing Equipment

ACS maintains advanced diagnostic and test systems capable of evaluating boards at the component, circuit, and system level. These include oscilloscopes, waveform analyzers, and precision test benches designed for logic and control applications.

Every repair includes:

- In-circuit testing to locate component-level faults.

- Functional simulation to confirm system behavior under operating conditions.

- Burn-in testing to identify intermittent or temperature-dependent issues.

- Calibration and quality control verification to ensure long-term reliability.

The company’s in-house quality assurance process ensures that each board is returned in fully functional condition, meeting or exceeding the original performance standards. This attention to detail helps customers restore confidence in their control systems without the delays and expense associated with OEM replacements.

Trained Technicians and Quality Assurance

ACS Industrial Services employs experienced electronics repair specialists who work exclusively with industrial-grade equipment. Each technician is trained to evaluate, rework, and test complex assemblies using precision tools and standardized procedures.

Quality control personnel inspect every completed unit before it is shipped. This inspection includes both electronic validation and physical checks to verify that no defects remain. The goal is consistent performance from the moment the board is reinstalled in the customer’s equipment.

Fast Turnaround & Warranty Protection

ACS understands that downtime affects productivity, customer schedules, and revenue. That is why turnaround times are tightly managed, with repair status updates available throughout the process.

- Standard Turnaround: Most logic board repairs are completed and shipped within approximately three weeks.

- Rush Repair Service: Expedited repairs are available, with return shipping in as little as three to five business days.

Each repaired logic board is backed by a two-year warranty covering both parts and labor. Unlike limited warranties that cover only the replaced component, ACS’s warranty applies to the entire board. Every repaired unit is fully tested before shipment to verify functionality and long-term reliability.

Customers across the United States rely on ACS Industrial Services for consistent repair quality, fair pricing, and clear communication. The process is transparent from start to finish, ensuring that every client receives accurate information, timely service, and dependable results.

How the ACS Repair Process Works

ACS keeps the repair process straightforward, transparent, and customer-focused. Every step is designed to reduce downtime and eliminate uncertainty. From the moment a board arrives at the facility, it is logged, inspected, and handled according to a controlled workflow.

1. Submit Your Board

Customers begin by completing the Repair Form and shipping their unit to the ACS Industrial Services facility in Hickory, North Carolina. The form includes essential details such as equipment type, failure symptoms, and return instructions.

2. Free Evaluation

Once received, the logic board is inspected by a technician who identifies any visible damage and performs diagnostic testing. Within 72 hours, customers receive a detailed repair quote outlining the scope of work, turnaround estimate, and warranty coverage. There are no fees or obligations: customers pay only for shipping.

3. Repair and Testing

After approval, the logic board enters the repair queue. Components are replaced or reworked using precision soldering and OEM-quality parts. Once the repair is complete, the board undergoes extensive testing, including in-circuit checks and simulated load tests to confirm full functionality.

4. Return Shipping

Upon successful testing, the repaired unit is carefully packaged and shipped back to the customer. Every repaired logic board includes a two-year warranty covering both parts and labor.

"All you pay is shipping: no estimates, no surprises.”

This process reflects ACS’s commitment to reliable service and consistent communication. Each project is tracked from intake through completion, ensuring accuracy and accountability at every step.

Contact ACS Industrial Services

ACS Industrial Services serves industrial and commercial customers across the United States. Whether you manage an automated production line, HVAC system, or specialized control unit, the team can help restore your equipment to full working order quickly and dependably.

For questions or assistance, contact ACS using the information below:

- Phone: 800-605-6419

- Email/Contact Form: Repair Form or Contact Us with Your Inquity

Customer service representatives are available to discuss your repair needs, explain the process, and arrange expedited shipping for urgent cases.

Frequently Asked Questions

What types of logic boards can ACS repair?

ACS repairs a wide range of industrial and commercial logic boards, including those used in automation systems, robotics, HVAC controls, and packaging equipment.

How long does the logic board repair process take?

Standard repairs are typically completed in about three weeks. Rush Repair Service is available for expedited turnaround within three to five business days.

Do you offer rush repair or expedited options?

Yes. Rush Repair Service prioritizes your board in the production schedule and includes accelerated testing and shipment.

What if my board manufacturer isn’t listed?

Even if your manufacturer isn’t on the published list, ACS can usually repair the board. The company’s technicians have experience with hundreds of OEMs, including older and discontinued models.

What does the two-year warranty include?

The warranty covers both parts and labor for the entire logic board, not just the replaced components. It applies from the date of shipment and ensures peace of mind for every customer.

Related Services

ACS Industrial Services offers a full range of electronic and industrial repair capabilities to complement its logic board repair services: